Technology

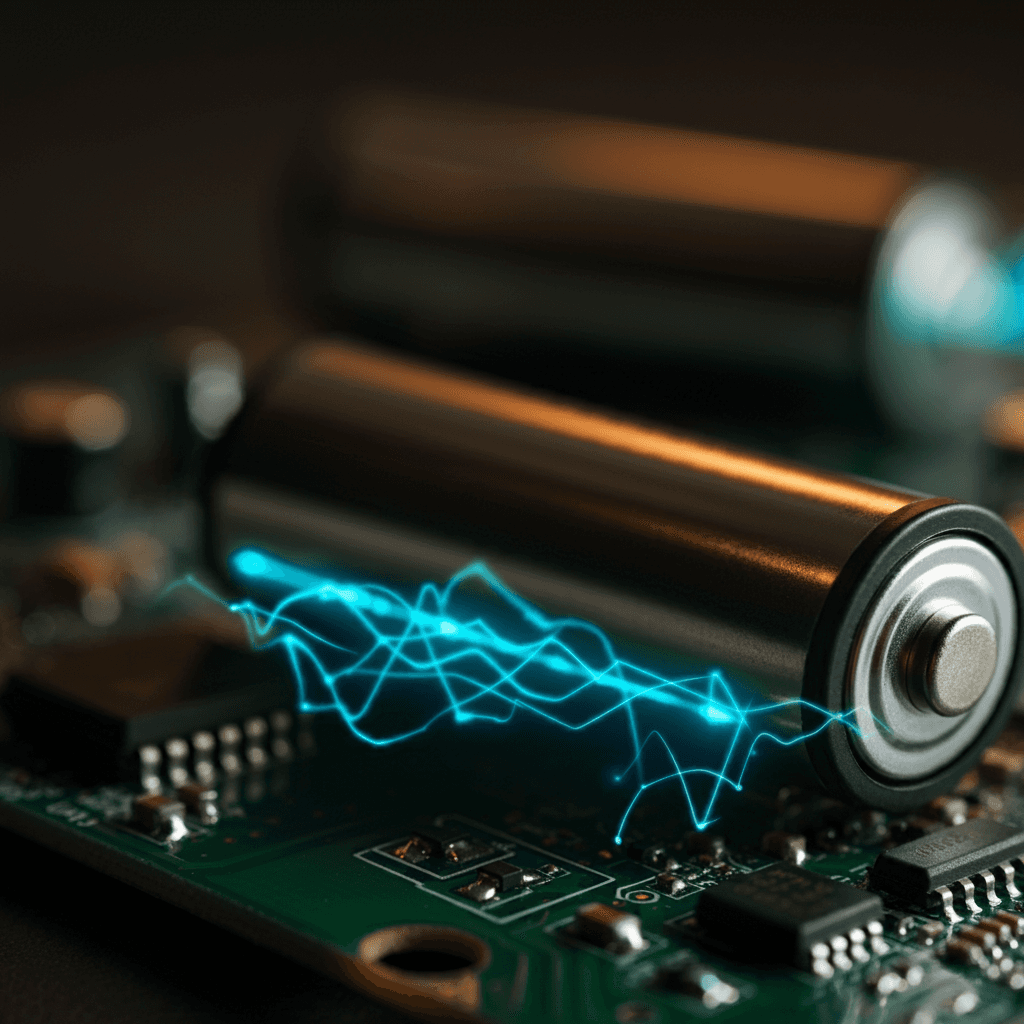

We support safe operation and extended lifespan of batteries through accurate data analysis and predictive modeling, providing optimized solutions for electric vehicle (EV) and energy storage system (ESS) batteries.

Technology

We support safe operation and extended lifespan of batteries through accurate data analysis and predictive modeling, providing optimized solutions for electric vehicle (EV) and energy storage system (ESS) batteries.

Technology

We support safe operation and extended lifespan of batteries through accurate data analysis and predictive modeling, providing optimized solutions for electric vehicle (EV) and energy storage system (ESS) batteries.

What is Cloud BMS?

What is Cloud BMS?

Providing various battery diagnosis functionsas a service based on the cloud that customers want in a cloud computing service model

Providing various battery diagnosis functionsas a service based on the cloud that customers want in a cloud computing service model

① Providing real-time status diagnosis solutions

Status diagnosis

technology

Status diagnosis

technology

Status diagnosis

technology

Goal

Suggesting classification criteria for Second Life

Suggesting classification criteria for Second Life

Real-time detection for accident prevention

Real-time detection for accident prevention

Providing criteria for determining battery value by customer

Providing criteria for determining battery value by customer

Research direction

Discovery of parameters (characteristics) reflecting the status

Discovery of parameters (characteristics) reflecting the status

Analysis of degradation mechanisms under operating conditions

Analysis of degradation mechanisms under operating conditions

Presentation of battery value assessment criteria for each customer through diagnostic verification and analysis.

Presentation of battery value assessment criteria for each customer through diagnostic verification and analysis.

Customer provided

Analysis results app/web provided

Analysis results app/web provided

Inspection report, battery value

Inspection report, battery value

② Accident prevention possible

Exceptional predictive technology

Exceptional predictive technology

Exceptional predictive technology

Goal

Predicting maintenance timing considering user patterns

Predicting maintenance timing considering user patterns

Accident prevention through prediction

Accident prevention through prediction

Presenting the predicted cause of the accident

Presenting the predicted cause of the accident

Research direction

Analysis of the mechanism causing defects

Analysis of the mechanism causing defects

Analysis of possible abnormal scenarios during operation

Analysis of possible abnormal scenarios during operation

Qualitative/Quantitative Diagnostic Analysis of Abnormal Causes

Qualitative/Quantitative Diagnostic Analysis of Abnormal Causes

Customer provided

Analysis results app/web provided

Analysis results app/web provided

Inspection Report

Inspection Report

③ Cost reduction possible

Lifespan prediction/extending technology

Lifespan prediction/extending technology

Lifespan prediction/extending technology

Goal

Securing cost-effectiveness through optimization of operating conditions

Securing cost-effectiveness through optimization of operating conditions

Presenting optimal driving conditions to prevent accidents

Presenting optimal driving conditions to prevent accidents

Research direction

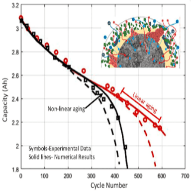

Analysis of the impact on lifespan according to the degradation mechanism

Analysis of the impact on lifespan according to the degradation mechanism

Analysis of battery operating patterns by user

Analysis of battery operating patterns by user

Customer provided

Analysis result app/web provided

Analysis result app/web provided

Inspection report, battery value

Inspection report, battery value

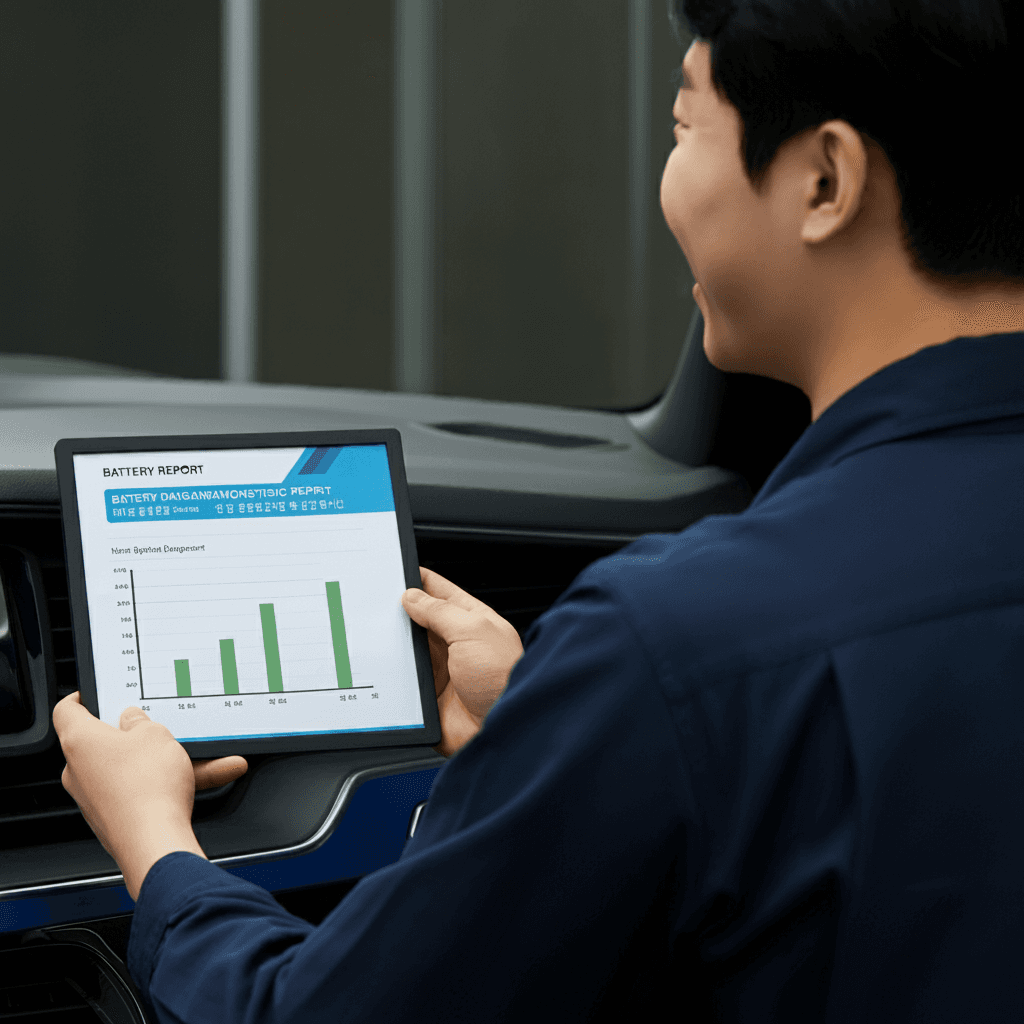

Battery diagnosis

Battery diagnosis

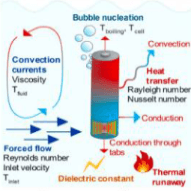

Development of a diagnostic model based on condition-reflecting indicators for accurate and rapid diagnosis and verification of the diagnostic model through cell decomposition analysis to check the internal state of the battery

Development of diagnostic models based on condition indicators for accurate and rapid diagnosis and verification of diagnostic models through cell decomposition analysis to check the internal state of the battery

- 1

전기자동차, 에너지저장장치 등 배터리 데이터 입력

- 2

모델 입력 매트릭스 구성 배터리 상태 추정 모델

- 3

수명/이상 예측 모델

- 4

Diagnosis result provided to the customer

- 5

Total battery solution for care throughout the battery life cycle

- 1

전기자동차, 에너지저장장치 등 배터리 데이터 입력

- 2

모델 입력 매트릭스 구성 배터리 상태 추정 모델

3

3수명/이상 예측 모델

4

4Diagnosis result provided to the customer

5

5Total battery solution for care throughout the battery life cycle

- 1

전기자동차, 에너지저장장치 등 배터리 데이터 입력

- 2

모델 입력 매트릭스 구성 배터리 상태 추정 모델

- 3

수명/이상 예측 모델

- 4

Diagnosis result provided to the customer

- 5

Total battery solution for care throughout the battery life cycle

Key technologies

Key technologies

Battery material surface analysis/ Composition analysis/ Structural analysis performed

Battery material surface analysis/ Composition analysis/ Structural analysis performed

⓵ STEP

⓵ STEP

Analysis of degradation mechanism

Analysis of degradation mechanism

Analysis of degradation mechanism

⓶ STEP

⓶ STEP

Development of status/abnormal indicators

Development of status/abnormal indicators

Development of status/abnormal indicators

⓷ STEP

⓷ STEP

Decomposition analysis diagnostic model validation

Decomposition analysis diagnostic model validation

Decomposition analysis diagnostic model validation

Analysis of degradation causes and securing diagnosis accuracy

Analysis of degradation causes and securing diagnosis accuracy

Apply accurate condition estimation indicators and ensure diagnostic accuracy through root cause analysis of degradation

Development of diagnostic models based on status-reflecting indicators for accurate and rapid diagnosis, and verification of the diagnostic model through cell decomposition analysis to check the internal status of the battery.